Thermocol Pipe Sections

Price 65 INR/ Bundle

Thermocol Pipe Sections Specification

- Usage & Applications

- Thermal insulation of hot and cold water pipes, air conditioning ducting, refrigeration, industrial pipelines

- Material

- Expanded Polystyrene (EPS) Thermocol

- Grade

- Standard/Economy/High Density (as per requirement)

- Tensile Strength

- >200 kPa

- Density

- 12 Gram per cubic centimeter(g/cm3)

- Heat Deflection Temperature

- 80C

- Width

- Standard 1 meter (can be customized)

- Length

- 1000 mm (custom lengths available)

- Thickness

- 10 mm to 100 mm

- Color

- White

Thermocol Pipe Sections Trade Information

- Minimum Order Quantity

- 30 Bundle

- Supply Ability

- 30 Per Day

- Delivery Time

- 1 Days

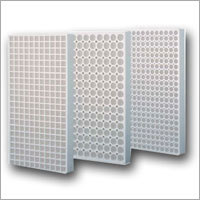

About Thermocol Pipe Sections

We have constructed a sound manufacturing unit, where we manufacture and supply a quality range of Thermocol False Ceiling. This range of ceiling is ideal for making moisture and heat resistant warehouse and storage rooms. To process this ceiling, we use finest quality sheets of low density polystyrene. Offered Thermocol False Ceiling can withstand various kinds of loads and vibrations. We offer this ceiling at pocket friendly prices and deliver to clients within the given time frame.

Features:

- Can withstand high heat

- Smooth texture

- Easy to install

Thermocol False Ceiling :

We offer Thermocol False Ceiling. Because of its closed cell structure, it offers a remarkable resistance to unwanted heat, chill and moisture to penetrate through it and also gives a rigid, structurally strong product to withstand various kind of loads and vibrations. It does not decay or age with the time and gives permanent life long insulation without regular maintenance. Perfect, even and plain surface makes its suitable to opt it for false roofing and easy to install, carry and plastering on it.

Advanced Thermal Performance

Our EPS Thermocol Pipe Sections provide outstanding insulation, safeguarding pipelines against temperature fluctuations. This not only boosts energy efficiency but also helps maintain optimal operational temperatures for both hot and cold systems. With a high heat deflection threshold of 80C, these sections deliver consistent thermal protection in challenging settings.

Adaptable to Your Project Needs

Designed for versatility, these pipe sections come in a standard 1-meter width and 1000 mm length, with options for custom sizing. Whether your requirements involve residential plumbing, large-scale HVAC installations, or specialized industrial applications, the size and grade selections make integration seamless and convenient.

Quality Manufacturing, Consistent Results

Produced in India by reputable suppliers, our Thermocol Pipe Sections are rigid, lightweight, and easy to handle. With a density of 12 g/cm and tensile strength exceeding 200 kPa, they ensure durability and resistance to physical stress while maintaining effective insulation throughout their service life.

FAQs of Thermocol Pipe Sections:

Q: How are Thermocol Pipe Sections used in thermal insulation applications?

A: Thermocol Pipe Sections are fitted around pipes to form a protective thermal barrier, minimizing heat loss or gain. They are commonly used for hot and cold water lines, air conditioning ducting, refrigeration systems, and industrial pipelines to enhance energy efficiency and maintain the correct temperature within the pipes.Q: What are the advantages of using EPS Thermocol Pipe Sections?

A: EPS Thermocol Pipe Sections offer lightweight construction, strong thermal insulation, resistance to moisture, and high tensile strength. These properties ensure lasting performance and reliable temperature control, while their easy-to-cut and install design makes them practical for a broad range of projects.Q: When should I choose customized sizes or thicknesses?

A: Custom sizes or thicknesses are recommended when your project involves non-standard pipe diameters, has unique spatial constraints, or requires tailored insulation performance. Manufacturers can adjust both length and width to suit your precise installation requirements.Q: Where can I use these Thermocol Pipe Sections?

A: These pipe sections are suitable for use in various settings, including residential buildings, commercial spaces, cold storage units, air-conditioned environments, and industrial facilities requiring temperature regulation for water, coolant, or process fluid pipelines.Q: What grades are available, and how do I select the right one?

A: Thermocol Pipe Sections come in Standard, Economy, and High Density grades. The choice depends on your insulation needs and budget. High Density is ideal for demanding, high-stress environments, while Standard and Economy grades suit routine insulation tasks.Q: What is the manufacturing process for EPS Thermocol Pipe Sections?

A: EPS Thermocol Pipe Sections are produced by expanding polystyrene beads under controlled conditions, molding them into pipe shapes, and then curing them to the desired size and density. This process results in consistent, high-performance insulation products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermocol Packing Materials Category

Thermocol Sheets

Price 65 INR / Bundle

Minimum Order Quantity : 30

Size : Customizable

Color : White

Width : Up to 1.2 meters

Length : Up to 2.4 meters

Airiator Floats for Aquaculture Farms

Price 190 INR / Number

Minimum Order Quantity : 150

Size : 950 mm x 350 mm x 350 mm

Color : Blue

Width : 350 mm

Length : 950 mm

Thermocol Fish Box 40 Litrs

Price 65 INR / Bundle

Minimum Order Quantity : 30

Size : 600x400x170mm Inner measurements with 30 mm thickness

Color : White

Width : 460 Millimeter (mm)

Length : 660 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS